Excellence in Manufacturing of Fittings & Metal Components

Gajanan Brass was established in the year 2008 as manufacturer of Brass Engineering Precision Turned Components & Fittings. Over the years we have continuously upgrade our systems and technology to provide our customers with best quality at competitive rates.

Gajanan Brass is one of the leaders in global market who believe in using latest technologies and facilities to manufacture products. With highly skilled work force, the company is able to fulfil any requirement of clients at stipulated period.

- Best Quality Products

- Custom Product Manufacturing

Our Products

Why Gajanan Brass is Your Trusted Partner for Business Success

16+

Years of Industrial Experience

98%

Client Success of Satisfaction Rate

10+

Global Reach In Countries

Customized Solutions

Expertise In This Field

Innovative Manufacturing Unit

Cost Effective Price

Quality Management System

Highly Trained Human Assets

Manufacturing Facilities

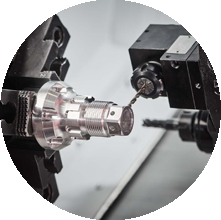

Our commitment to excellence extends to our state-of-the-art infrastructure, which plays a pivotal role in delivering top-quality metal components and services. We prioritize excellence through our state-of-the-art in-house manufacturing facility, equipped with cutting-edge machinery and operations leveraging innovative technologies. The industrial landscape boasts the latest and ultra-modern automatic equipments that defines the pinnacle of technological advancement, managed by a team of highly experienced and skilled staff dedicated to producing materials of controlled quality.

Simple Step To Get Components

1

Raw Material

First step of production is to purchase the raw material (Brass Rods) form our trusted and verified supplier. Material are to be purchased as per the standard material grade or customer's specification.

2

Manufacturing

Manufacturing process are Threading, Drilling, Facing, Milling and Cutting. Expert engineers are responsible for taking care of measurement, dimensions and quality checking of products.

3

Quality Control

After product produced, it has been send to QC Department. Quality Control Supervisor will check all dimensions and Measurements on the basis of various quality checking methods.

4

Packaging & Dispatch

After inspection, each order is directed to a packing location and whole order is checked here. Than the packing list gets printed and the whole order is packed and dispatched.

Get Latest Company Catalogue

Kindly download our latest company catalogue to get complete details on our products and services. Here you will find all information regarding our product images, specifications, etc.