Pioneering The Art of Precision

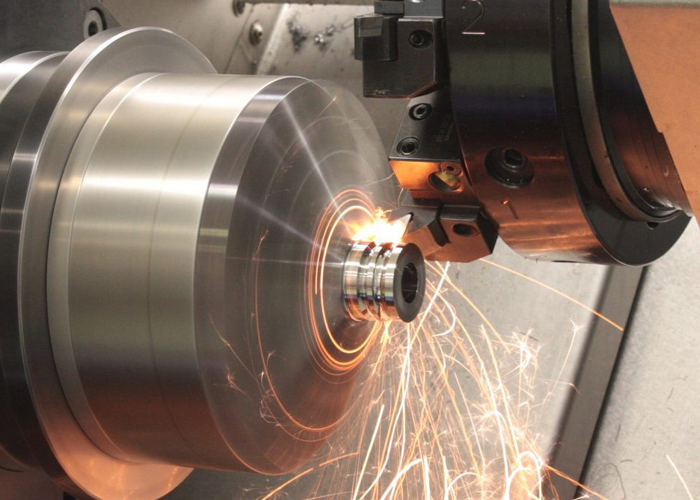

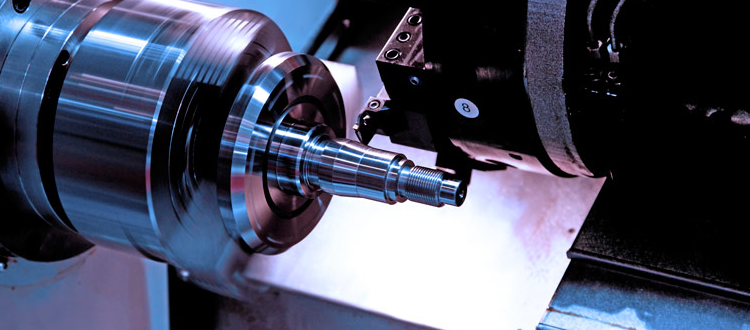

Our manufacturing facility is a testament to our dedication to precision and quality. With cutting-edge machinery and technology, we have the capability to produce customized metal components to exact specifications. Our team of skilled professionals operates in a safe and organized environment, ensuring the highest standards of production.

Efficient warehousing and logistics are crucial to our commitment to timely deliveries. We maintain a well-organized warehouse to store our products safely before shipment. Our infrastructure is a reflection of our dedication to innovation, quality, and environmental sustainability. We take pride in the advanced facilities and processes that empower us to meet and exceed the expectations of our customers.

Facilities & Units

Manufacturing Process

Capabilities

| Raw Material : | » Brass, Copper, Stainless steel, Aluminum and Non-Ferrous material | Miling Size : | » 2mm to 60mm |

| Surface Treatment : | » Nickel, Tin, Zinc, Silver, Chrome, Lead, Anodize | Drilling Size : | » 4mm to 50mm |

| Documentation : | » PPAP Level III | Sloting Size : | » 10mm to 40mm |

| Packing : | » Boxes, Plastic bubble bags, Cotton bags, Nonvonue bags, Gunny bags | Forging Size : | » 10mm to 200mm |

Get Latest Company Catalogue

Kindly download our latest company catalogue to get complete details on our products and services. Here you will find all information regarding our product images, specifications, etc.